An electrical panel is the core of any power distribution system. One of the most important steps in this process is wire management and cable routing. Without proper handling of these parts, the system may face safety issues, maintenance problems, and even total failure. Let us look at why proper wire management is necessary during the electrical panel assembly and how it affects both quality and long-term performance.

What Does Wire Management Mean in Panel Assembly?

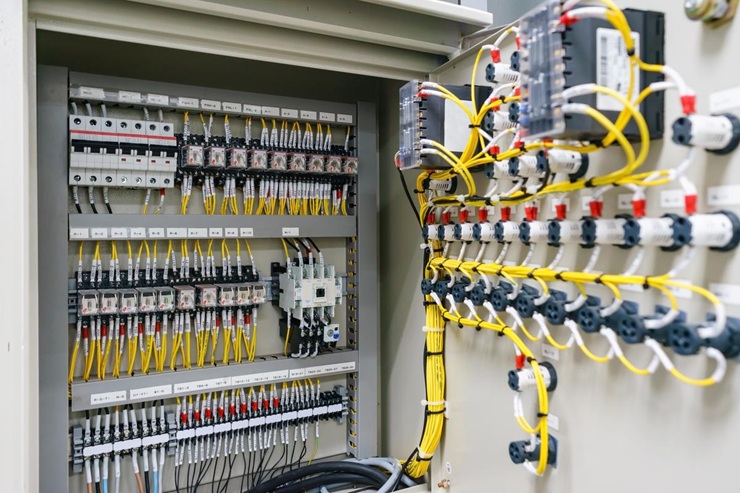

Wire management refers to the way wires and cables are placed, fixed, grouped, and protected inside an electrical panel. It includes arranging them in clear paths, separating high and low voltage lines, avoiding sharp bends, and using clips or ducts to hold them in place.

In the fabricación de cuadros eléctricos, cable routing is done based on a wiring diagram. It follows a layout that matches the components inside the panel such as breakers, relays, terminals, and contactors. The goal is to make the internal layout clean, clear, and easy to follow.

Why Is It Important for Safety?

A messy wiring setup increases the risk of accidents. Loose wires may rub against sharp panel edges or overheat if they touch other cables. Improper routing can create stress on the insulation or cause short circuits when wires are crossed carelessly.

Good wire management avoids these risks. Each wire is placed in a clear position, with enough space from heat-producing components. This prevents accidental contact and makes the panel safer for both installation and operation.

How Does It Affect Maintenance and Troubleshooting?

A poorly routed cable system makes it harder to trace a fault. If wires are tangled or run without a fixed route, it becomes difficult to find the source of a problem. Even a simple fuse change may take longer due to unclear wiring paths.

During the electrical panel assembly, organizing cables neatly helps in future maintenance. Labels are easier to read. Technicians can follow the diagram without confusion. Downtime is reduced, and errors during repair are less likely to occur.

Does It Improve Panel Performance?

Yes. When wires are routed correctly, electrical signals move with fewer interruptions. Separating power lines from signal wires reduces noise and interference. Bends and loops in power cables increase resistance and heat buildup. Clean routing avoids these issues.

In panels with programmable logic controllers or sensitive electronics, poor cable layout can cause signal loss or false triggering. A well-managed wiring system supports steady and reliable operation under different load conditions.

What Are the Best Practices for Cable Routing?

During the electrical panel assembly, some best practices include:

- Using separate paths for power and control wires

- Grouping wires based on function or destination

- Avoiding tight bends that strain the conductor

- Fixing wires with clips, ducts, or cable ties at regular intervals

- Leaving slack only where movement or service is expected

- Labelling wires for quick identification

These methods do not just improve the look of the panel. They also support performance and extend the service life of the system.

Conclusion

Wire management and cable routing are not just minor steps in panel assembly. They are key parts of the process that affect safety, performance, maintenance, and durability. In every stage of the electrical panel assembly, clean and planned wiring leads to better results.

For manufacturers and technicians alike, giving attention to wire routing is a smart and necessary part of building panels that perform well in the field and stay reliable for years to come.

Leave a comment